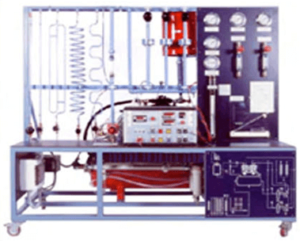

The unit allows to study the main features of single-stage air compressor. The wheeled bench is equipped with a front panel, on which are placed the devices and all necessary tools to carry out the tests.

TRAINING PROGRAM

• System start up

• Inlet and Outlet compression temperatures measurement

• Inlet Compressor air flow rate measurement

• Power and efficiency of an alternative compressor

• Air flow rates with unified throttling devices measurements

• Compressor performance at variable speed

TECHNICAL SPECIFICATIONS

Two-cylinder reciprocating single stage compressor

Driven by a belt drive from an electric motor c.a. with frequency variator:

• Vacuum gear and pilot valve

• Supply check valve

• Flow rate: 260 l/min (referred to the suction conditions)

• Max delivery pressure: 9 bar

• Rpm sensor

Air tank:

• Capacity: 100 l

• 0÷10 bar dial gauge

• 1÷9 bar adjustable pressure switch, for compressor insertion and deactivation

• Safety valve

• Exhaust valve

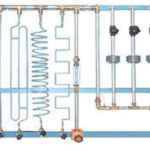

Device for measuring the air flow aspirated by the compressor:

• Calibrated flange mounted on damping vessel

• Differential micromanometer with inclined scale for measuring the differential pressure at the flange

Electric control panel:

• Digital multimeter to measure: voltage, current and power drive motor

• N. 2 digital thermometers for instant reading of the temperature

• Differential magnetothermal switch

• Voltage presence warning lamp

• Power supply: 230 Vac 50 Hz single-phase – 2,2 kVA (Other voltage and frequency on request)