The unit enables the study of pressure loss in different kinds of compressed air circuits. The device needs an air compression system and must be used with one of the following compressor Study Units.

TRAINING PROGRAM

• Test and calibration of the safety components (pressure switch, pilot valve)

• Measurement of load losses in different types of pipes

TECHNICAL SPECIFICATIONS

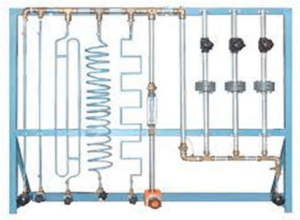

Unit for measuring flow rate and head loss

• N. 3 calibrated diaphragms as per UNI standards, dimensions for a full scale flow rate of 300 I/min, mounted on a 3/4” pipe and complete with a throttle valve downstream from the pipe and pressure intake

• N. 5 pipes of different diameter, shapes and length, for the determination of load losses in function of the air capacity complete with a throttle valve downstream from the pipe and pressure intake

• Pressure reduction valve

• Flow meter for measuring the air flow rate with regulation field from 0 to 25000 I/h

• Differential U-shaped manometer 0 to 300 mmHg for measuring the differential pressure of the calibrated diaphragms and pressure drops in the pipes of different sections

• N. 2 Pt100 thermo-resistances for measuring air temperature upstream of the calibrated diaphragms and pipes being tested

• N. 2 Bourdon gauges 0 to 10 bar