Most of the world’s electricity production is met by steam turbine systems, in which it is important to optimize both power production with multistage turbine and thermal efficiency to consume the least possible amount of fuel.

The simulator studies the operation of a subcritical base system with overheating of the steam that enters the

turbine, where it generates electric power, and returns to the thermal generator after being condensed and pumped.

To increase the thermal efficiency, numerous technological devices have been added over time, especially with regard to steam generator, which will be analyzed in the simulation.

TRAINING PROGRAM

• Steam system thermodynamic:

– Plant scheme

– Thermodynamic efficiency calculation

– Operating fluid mechanics (water)

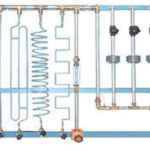

– Sizing of steam generator

– Examples of advanced technologies: subcritical with re-heating, subcritical with steam bleeding and supercritical cycle

• Power generation:

– Total power generated

– Design model of steam turbine

– Off-design model of steam turbine

– Examples of typical expanders (single and multi-stage)

– Electric drives

TECHNICAL SPECIFICATIONS

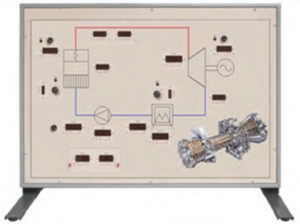

The simulator consists of:

• Desktop vertical panel that works together with a PC (not included)

• Color screen-printed plate reproducing the cross section of a steam turbine, showing the layout of the propulsion elements

• Electrical checks

• Display for basic parameters

Software

The supplied software allows the panel parameters view and the settings modification.

Selectable specifications:

• Water flow setting by potentiometer

• Fuel flow setting by potentiometer

• Shaft power setting by potentiometer

• ON-OFF power generator via analog button

• Switches for:

– integration with exchanger (re-heating)

– steam bleeding cycle

– supercritical cycle

Programmable specifications:

• On-design operation:

– INPUT: water and fuel flowrate

– OUTPUT: power generation

• Off-design operation:

– INPUT: water flowrate and mechanical power

– OUTPUT: fuel flowrate

• Turbo-expansion: possibility to choose 2 different types of turbine

• Heat generation: possibility to choose 3 different types of steam generator with 3 different fuels

• Thermal recovery: possibility to choose 2 different heat exchangers with different performance

• Bleeding: single or double with additional circulation pump

• New generation system: superheating steam plant

• Power supply: 230 Vac 50 Hz single-phase – 400 VA (Other voltage and frequency on request)