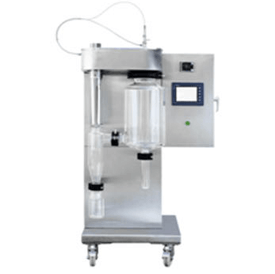

Spray drying is a rapid and efficient method for obtaining powdered products from solutions. If compared to freeze drying, this technique ensures higher production potentialities and shorter execution times. Very short residence times and the refrigerating effect due to solvent evaporation make it the ideal method for drying thermosensitive products. This spray dryer has been designed for educational and research laboratories and it enables to obtain the product micronized in short time, as well as valid data for scale up. All the parts in contact with the product are of stainless steel and of borosilicate glass.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Drying of aqueous solutions by atomization

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Temperature programmable up to 250°C

• Touch screen control panel

• Built-in compressor

• Variable speed fan

• Heating system of 3000 W

• Peristaltic pump adjustable up to 1500 ml/h

• Atomization system with spray nozzle of stainless steel and cleaning device

• Drying chamber of borosilicate glass with vessel of borosilicate glass for collecting bottom product

• Cyclone of borosilicate glass with bottle of borosilicate glass for collecting the sample

• Exhaust pipe for exhausted vapours

• Power supply: 230 Vac 50 Hz single-phase – 3 kVA (Other voltage and frequency on request)