Description

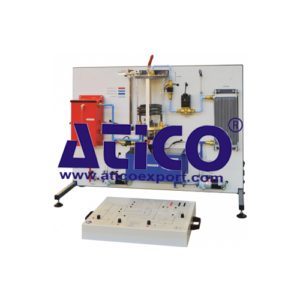

Process Trainer is an educational package that mimics industrial process engineering. The fully integrated, self-contained teaching apparatus gives a comprehensive range of process control experiments, from basic to advanced. Using water as the working fl uid, the equipment allows safe, practical experiments on control of fl ow, liquid level, temperature and pressure. Students can study each of these separately or in combinations. The equipment consists of an experiment module, a control module and software. The experiment module includes all the essential parts to allow students to create process control systems. The main part is the process vessel, with a stirrer, a temperature sensor, level and pressure sensors, a heat exchanger and vent valve. It also includes two loops, linked by the heat exchanger in the process vessel. One loop is the heating loop with pump, heater tank and heater. The other loop is a process and cooling loop with pump, cooler, fan, valves and reservoir. The control module links to the experiment module to provide access to the connections of each part on the experiment module. It includes a clear mimic diagram with switches and controls to allow manual control of pump speed, cooler-fan speed, heater power and stirrer. It also includes sockets and a built-in computer interface. This allows the user to link each part of the experiment module to a suitable computer (not included) for remote control and data acquisition. Supplied with the equipment is Control Software for supervisory control of the and data acquisition. You need a suitable computer to use the software.

Learning Outcomes

Proportional, Integral and Derivative (PID) control

Control of flow

Control of level

Control of pressure

Control of temperature

Ratio control

Cascade control

Multi-loop control

Interacting control loops

Specifications

ATICO is committed to a programmed of continuous improvement; hence we reserve the right to alter the design and product specification without prior notice.

Dimensions:

• Experiment module: 800 mm x 1000 mm x 450 mm

• Control module: 80 mm x 500 mm x 370 mm

• Packed for export: 0.5 m3

Weights:

• Experiment module: 40 kg

• Control module: 7 kg

• Packed for export: 80 kg

Clear process vessel with:

• Heat exchanger coil

• Stirrer

• Vent valve

• Pressure transmitter

• Level transmitter

• Temperature transmitter

• Drain valve

Heating loop with:

• Heater tank with heater

• Low level fl oat switch

• Temperature transmitter

• Circulation pump

• Heat exchanger output/tank return temperature transmitter

• Heater loop fl ow rate transmitter

• Over-temperature safety device

Process and cooling loop with:

• Cooling radiator and fan

• Reservoir (with low-water level switch)

• Circulation pump

• Temperature transmitter (at inlet to the cooling radiator)

• Temperature transmitter (at outlet of the cooling radiator)

• Flow transmitter

• Proportional valve

• Process loop bypass valve

Operating Conditions

- Operating environment: Laboratory

- Storage temperature range: –25°C to +55°C (when packed for transport)

- Operating temperature range: +5°C to +40°C

- Operating relative humidity range: 80% at temperatures < 31°C decreasing linearly to 50% at 40°C