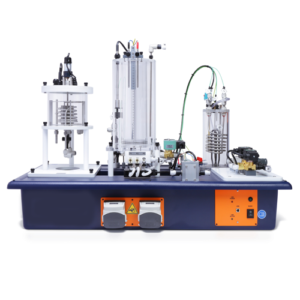

Description:

It includes a variable volume process tank, a hot water tank with electric heater and indirect heating/cooling coil, a hot water pump, two non-dedicated pumps, three on/off solenoid valves and a proportioning valve. The instrumentation includes temperature sensors, two differential water pressure sensors, a mechanical level sensor (float switch) and an electronic level sensor (conductivity). The inlets and outlets of the various pumps, valves and tanks incorporate self-sealing quick release fittings. This enables the configuration to be quickly changed, offering a wide variety of different loops.

Specification:

A multi-function process control teaching system, capable of demonstrating level, flow, pressure and temperature control loops

• Bench mounted and includes a built-in USB computer interface

• Options include: reactor vessel with conductivity measurement, pH measurement, pneumatic control valve and electronic console

• Includes the following process control demonstrations:

Process principles

- Calibration of sensors (via PC software)

- Inflow control

- Outflow control

- Direct heating

- Indirect heating

- Batch operation

- Continuous operation

- Effect of sensor lag (eg thermometer pocket)

- Effect of system time constant (eg volume change)

- Effect of dead time (eg holding tube)

- Effect of mixing/stirring (requires PCT41)

Measured variables

- Level – on/off switch (fixed hysteresis)

- Level – differential on/off switch (adjustable hysteresis)

- Level – proportional pressure sensor (slow system response)

- Flow – proportional turbine sensor

- Temperature – on/off switch (fixed hysteresis)

- Temperature – proportional thermocouple sensors

- Static pressure – proportional sensor (fast system response)

- Differential pressure – proportional pressure (fast system response)

- pH – proportional sensor(requires PCT41 and PCT42)

Controller types

- Manual control

- Effect of reverse/direct action

- On/off output with hysteresis

- Time proportioned output with adjustable P, I & D terms and cycle time

- PID proportional output with adjustable P, I & D terms

- Remote setpoint control (requires PCT41)

- Ratio, cascade and feedforward with feedback loops (requires PCT41)

Controlled variables

- On/off flow control via solenoid valves

- Time proportioned flow control via solenoid valves

- Proportional flow control via pump speed

- Proportional flow control via electrical proportioning valve

- Proportional flow control via pneumatic proportioning valve (requires PCT44)

- On/off heater power control via solid state relay

- Time proportioned heater power control via solid state relay

- Proportional heater power control via solid state relay