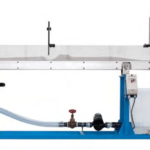

The hydraulic bench represents a service unit for a wide variety of complementary accessories that enable to perform several experiments of fluid mechanics. The upper part of the bench consists of a work top equipped with an open channel above which the accessories are placed, and of two tanks that enable to carry out some volumetric measurements of the flow rate by using a level gauge. The bottom of the volumetric tank is equipped with a valve in

order to drain the water in the supply tank. The water is drawn to the top of the bench by a centrifugal pump, whereas the flow rate is adjusted through a control valve and measured with a variable area flowmeter. The variable-area flowmeter enables to compare the flow rate read on the instrument with the flow rate measured through the measuring tanks.

TRAINING PROGRAM:

• Volumetric measurement flow rate

• Calibration of a variable area flowmeter

• Characteristic curve of a centrifugal pump

TECHNICAL CHARACTERISTICS:

• Hydraulics bench, mounted on wheels with brakes, with AISI 304 stainless steel frame, valves and pipes

• Centrifugal pump of stainless steel – 0.37 kW, maximum flow rate of 80 l/min, maximum head of 20 m

• Pressure gauge on the suction and on the discharge of the pump

• AISI 304 stainless steel feeding tank: capacity 120 litres

• Feeding tank made of plastic material: capacity 120 litres

• Variable-area flowmeter, range 0,4-4 m³/h

• AISI 304 stainless steel upper tank for volumetric flow measurement with 10 litres capacity – for low flow rates – and with 40 litres capacity – for high flow rates

• Upper tank made of plastic material for volumetric flow measurement with 10 litres capacity – for low flow rates – and with 40 litres capacity – for high flow rates

• Control valve for adjusting flow rate

• Drain valve on the base of the upper tank for water recycling inside the supply tank

• Work top with open channel

• Power supply: 230 Vac 50 Hz single-phase – 0.6 kVA (Other voltage and frequency on request)