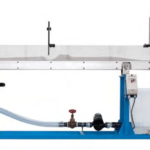

Horizontal Fluid Friction Plant

Teaching Objectives of:

Horizontal Fluid Friction Plant

- Study of the principal elements in an installation of piping.

- Measurement of pressure losses generated by these various elements by means of manometric panel or/and electronic probe with transmitter.

- Visualization of the flows in the pressure reducing conduits and orifices

- Observation of the modes of laminar flow and turbulent according to the flows and pressures

Study of the regular pressure losses of:

- Piping of various diameters

- Piping smooth and rough

- Piping rising, downward and tilted

Study of the individual pressure losses of:

- Elbows of various angles

- abrupt increase or reduction of the piping diameter

- various valves

Calibration of the pressure reducing orifices (venturi, diaphragm)

Measurement of the flows by pressure reducing orifices (venturi, diaphragm)

Determination of Cv of the valves. - Technical specifications:

- Frame stainless equipped with casters, including two brakes

- A tank in transparent PVC with draining valve

- An industrial stainless body centrifugal pump

- A rotameter

- A membrane valve for controlling the flow

- Two pipe sections with diameters of 20 and 25 mm.

- Two pipe sections with a diameter of 15 mm, smooth and rough

- A piping with variable slope

- Elbows with 45°, 90° large and small ray and 135°

- A widening and an abrupt reduction Dn15-Dn25, in Altuglass

- A membrane valve

- A ball valve

- A cap valve

- A diaphragm in Altuglass

- A Venturi tube in Altuglass

- A device of dye injection

- A manometric panel with single and U-tubes.

- A differential pressure sensor.

- – A control cabinet on/off of the pump and protection

- – A set of manual valves

- – Handbook technical and teaching.

Equipment package:

- – A manometric panel for the measures of the pressure losses in the main system.

U-tubes to measure the differential pressures in the diaphragm and the venturi.

4 manometers for the measures of pressures between the valves and a manometric panel. - – A manometric panel for the measures of the pressure losses in the main system.

A differential pressure sensor for pressures measurements in the diaphragm, the venturi and in valves. - – A differential pressure sensor with display for all the pressures measurements.

Options :

- – Temperature probe and indicator

- – Programmable indicator for calibration of diaphragm and venturi.