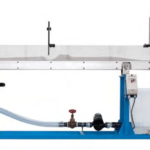

The trainer investigates the behaviour of a system in a two-shaft arrangement (vehicle drive, ship’s propulsion or generator drive) and of a jet engine (aircraft’s propulsion). At the core of the trainer are a so-called gas generator and a free-running power turbine. The gas generator consists of a radial compressor, a combustion chamber and a radial turbine. The compressor and turbine are mounted on a shaft. Depending on the arrangement, the energy of the exhaust gas stream is either converted into mechanical energy in the free-running power turbine (single-shaft arrangement) or accelerated and transformed into thrust via a nozzle (two-shaft arrangement). It is possible to convert from a single-shaft to a two-shaft arrangement in just a few actions.

The gas turbine works as an open cyclic process, with the ambient air being drawn out and fed back in. Intake and exhaust silencers reduce the noise in operation of the power turbine. The use of propane as the combustion gas ensures clean, odourless operation. A start-up fan is used to start the gas turbine. Relevant measuring values are recorded by sensors and indicated on the display and control panel. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included.

Learning Objectives And Experiments

- Familiarisation with the function and typical behaviour during operation of a gas turbine

- Operation as jet engine

- Operation as power turbine

- Determining effective power

- Thrust measurement

- Determining specific fuel consumption

- Recording the characteristic of the power turbine

- Determining the system efficiency

Features

- Operation with power turbine or as jet engine with propelling nozzle

- Simple model of a gas turbine

- Display and control panel with illustrative process schematic

- Propane gas as fuel

Specification

- Function and behaviour during operation of a gas turbine

- Single-shaft arrangement for operation as jet engine

- Two-shaft arrangement for operation with power turbine

- Start-up fan to start the gas turbine

- Asynchronous motor with frequency converter as generator

- Conversion of generated electrical energy into heat using four 600W braking resistors

Technical Specification

- Gas generator (compressor and high-pressure turbine)

- Speed range: 60000…125000min-1

- Max. Pressure ratio: 1:2,2

- Max. Mass flow rate (air): 0,125kg/sec

- Max. Fuel consumption: 120g/min

- Power turbine

- Speed range: 10000…40000min-1

- Mechanical power: 0…2kw

- Electrical power: 0…1,5kw

- Sound level at 1m distance: max. 80db(A)

- Temperature exhaust gas: 700°C

- Operation as jet engine

- Thrust measurement: 0…50N

- Sound level at 1m distance: max. 110db(A)

- Measuring ranges

- Temperature: 4x 0…200°C / 3x 0…1200°C

- Speed: 0…199999min-1

- Electrical power: 0…1999W

- Flow rate: 0…100L/s (air)

- Flow rate: 1,5…10,5kg/h (fuel)

- Fuel supply pressure: 0…25bar

- Nozzle pressure: 0…4bar (fuel)

- Combustion chamber pressure loss: 0…100mbar

- Pressure (inlet): 0…2,5bar (high-pressure turbine)

- Pressure (inlet): 0…300mbar (power turbine)

- 230V, 50Hz, 1 phase, 400V, 50Hz, 3 phases

- 400V, 60Hz, 3 phases, 230V, 60Hz, 3 phases