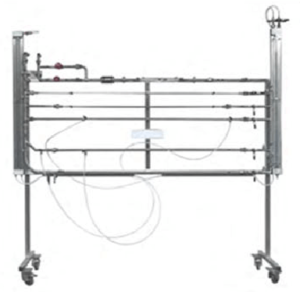

The module is used to study fluid friction losses through pipes of different diameters, valves and flow metering devices (Venturi tube, orifice plate and Pitot tube). The pipe to be tested can be selected through a valves system without being disconnected. The measurement of energy losses is carried out with a differential pressure gauge and a mercury pressure gauge.

TRAINING PROGRAM:

• Demonstrating the relationship between head losses and velocity of fluid

• Determining the head loss of a flow through pipes of different diameters, fittings and metering devices

• Determining the relation between friction coefficients and Reynolds’ number for flow through a pipe with roughened bore

• Demonstrating the application of different systems for measuring flow rate and fluid velocity

TECHNICAL CHARACTERISTICS:

• AISI 304 stainless steel structure

• Total number of tapping points= 36

• AISI 304 stainless steel pipes

• Internal diameter of test pipes: 17 mm, 11 mm, 7 mm, 4 mm

• Internal diameter rough pipe: 15 mm

• Length of test pipe: 1000 mm

• AISI 304 stainless steel 90°elbow

• AISI 304 stainless steel 45°elbow

• AISI 304 stainless steel 45° “Y”

• AISI 304 stainless steel “T”

• AISI 304 stainless steel sudden enlargement

• AISI 304 stainless steel sudden contraction

• Gate valve

• Bell valve

• Globe valve

• “Y” strainer

• Transparent venturi meter

• AISI 304 stainless steel orifice plate

• AISI 304 stainless steel Pitot tube

• Water differential pressure gauge, range 0-1000 mm

• Mercury differential pressure gauge, range 0-1000 mm