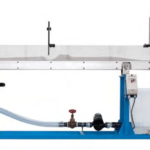

The equipment enables to measure the head loss of a liquid flowing through a circular pipe. It consists of a test pipe, oriented vertically, which may be fed directly from the hydraulics bench or from an internal tank with constant level. The flow rate can be adjusted by a valve on the discharge line of the pipe. Head loss between two tapping points in the test pipe is measured by a mercury pressure gauge for high flow rates, and a and a water pressure gauge for small flow rates. Water discharging from the head tank returns to the supply tank of the hydraulics bench.

TRAINING PROGRAM:

• Determining the friction factor in laminar and turbulent flow regimes

TECHNICAL CHARACTERISTICS:

• AISI 304 stainless steel structure

• AISI 304 stainless steel test pipe: internal diameter 4 mm

• Length of test pipe: 500 mm

• Distance between pressure tappings points: 500 mm

• Mercury manometer range 0-500 mm

• Water manometer range 0-500 mm

• AISI 304 stainless steel tank with constant level