Decription:

Based on a Peltier device, the Thermo-Electric Heat Pump demonstrates how electrical power can be used to extract heat from a cool surface and transfer it to a hot surface.

This designed for use with the Heat Transfer Service Unit.

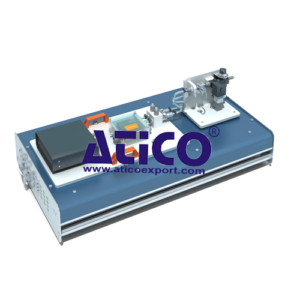

Based on a Peltier device, theThermo-Electric Heat Pump demonstrates how electrical power can be used to extract heat from a cool surface and transfer it to a hot surface. This effect is becoming widely used for point cooling (e.g. of semiconductor devices) and small-scale volumetric cooling.

The thermoelectric Peltier device is positioned in a heat transfer path, between two copper blocks. It extracts heat from one block (cold reservoir) and transfers it to the other block (hot reservoir). In order to measure the heat transfer rate, the cold reservoir is fitted with an electric heater, powered by the service unit. By varying the electric power into the system, the behaviour of the system at different operating points and temperatures can be established.

The heat extracted is transferred to the hot reservoir, together with heat generated by the electrical supply to the Peltier device. This heat is removed by a water-cooled heat exchanger. The flow rates can be adjusted to provide a range of operating temperatures.

Experimental Capability:

- Performance of a Peltier device as a cooler

- Heat transfer characteristics as a function of temperature and drive current

- Measurement of the coefficient of performance

- Energy balance

- Demonstration of a Peltier device as an electrical generator

Technical Specifications

- Small-scale accessory designed to demonstrate the use of a Peltier device to transfer heat across surfaces

- Comprises a Peltier device, a heater, and a water-cooled heat exchanger

- Heat transfer rates up to 68W

- Heater power, Peltier drive and cooling flow rate all fully electronically adjustable under computer control

- Service unit allows for measurement of cooling water temperatures and flow to allow an overall energy balance

- The accessory is mounted on a PVC baseplate, which is designed to sit on the heat transfer service unit without the need for tools

- A comprehensive instruction manual is provided