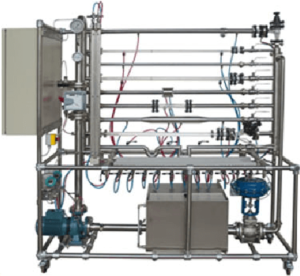

This equipment consists of a hydraulic circuit including pump and flowmeter and enabling to be connected with various hydraulic components, where the pressure drops on these elements can be measured. The automated version includes a PID controller for the automatic control of the flow rate of the water crossing the circuit.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determining pressure drops in pipes of different diameter

• Determining pressure drops in bends and elbows

• Determining pressure drops in pipe expansions and restrictions

• Measuring the flow rate with calibrated orifice and computing the discharge coefficient α

• Measuring the flow rate with Venturi tube and computing the discharge coefficient α

• Checking the laminar, transition and turbulent flows by tracer

• Verifying Bernoulli’s theorem

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Centrifugal pump with body and impeller of bronze, Qmax = 10 m3/h, H = 18 m

• Tank of AISI 304 stainless steel, with capacity of 80 l

• Variable area flowmeter of AISI 304 stainless steel, with range of 1 to 10 m3/h

• Angle valve (DN 25) of borosilicate glass, with plug of PTFE

• Diaphragm valve of borosilicate glass – DN 25

• Pipe of AISI 304 stainless steel of ½”

• Pipe of AISI 304 stainless steel of 1”

• Pipe of borosilicate glass DN15

• Pipe of borosilicate glass DN25

• Pipe of AISI 304 stainless steel with U and L bends

• Pipe of AISI 304 stainless steel with sudden expansion and restriction

• Pipe of AISI 304 stainless steel with calibrated orifice

• Pipe of AISI 304 stainless steel with Venturi tube of Plexiglas

• Pipe of borosilicate glass for checking the laminar and turbulent flows by tracer

• Tank of borosilicate glass, with capacity of 1 l, for tracer

• Bourdon gauge of AISI 304 stainless steel

• Stainless steel differential mercury gauge (mercury not supplied; the instrument can be replaced with a digital

pressure gauge on request during order placement)

• Thermometer with range of 0 to 100 °C

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase – 2 kVA (Other voltage and frequency on request)

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 10000 mm H2O and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Interface (included in the switchboard) for the connection with a PC

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Pneumatic valve of stainless steel

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 1000 mm H2O and 4-20 mA output signal

• Electronic differential pressure transmitter of stainless steel, range of 0 to 10000 mm H2O and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend