Compressed air for industry and businesses that use compressed air as an energy source is generated by means of so-called compressed air generation systems. A key component of these systems is the compressor. It converts the supplied mechanical energy into a higher air pressure. Compressed air generation systems are used to drive machines in mining, for pneumatic control systems in assembly plants or tyre inflation systems at petrol stations.

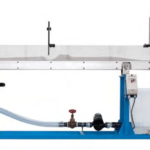

It includes a complete compressed air generation system with a two-stage compressor and an additional pressure vessel as intercooler. The trainer enables the recording of compressor characteristics and representing the compression process in a p-V diagram.

Learning Objectives And Experiments

- Design and function of a two-stage compressor

- Measurement of relevant pressures and temperatures

- Determination of the intake volumetric air flow rate

- Compression process on a p-V diagram

- Determination of the efficiency

Features

- Two-stage compressor with intercooler

- Compression process on a p-V diagram

Specification

- Recording the characteristic of a two-stage compressor

- Piston compressor with 2 cylinders in V-arrangement

- Intake vessel with nozzle to measure the intake volumetric flow rate, pressure sensor and additional manometer

- Pressure vessel after the first stage as intercooler

- Pressure vessel after the second stage with safety valve, blow-off valve and silencer as well as an additional manometer and a pressure switch

- Sensors for pressures, temperatures and electric power output

- Digital displays for temperatures, pressures, differential pressures and electric power output

Technical Data

- Compressor

- two-stage

- with 2 cylinders in a V-arrangement

- power consumption: 3kW

- speed: 710min-1

- intake capacity: 250L/min

- quantity delivered: 202L/min (at 12bar)

- operating pressure: 12bar, max. 35bar

- Intake vessel: 20L

- Pressure vessels, 16bar; capacity:

- after 1st stage: 5L

- after 2nd stage: 20L

- Safety valve: 16bar

Measuring ranges

- differential pressure: 0…25mbar

- pressure: 1x 0…1,5bar; 2x 0…16bar

- temperature: 4x 0…200°C

- power: 0…3500W

- 400V, 50Hz, 3 phases

- 400V, 60Hz, 3 phases

- 230V, 60Hz, 3 phases