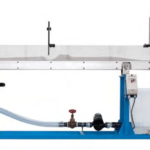

Radial Fans Are Used To Transport Gases With Non-Excessive Pressure Differences. The Medium Is Drawn In Axially To The Drive Shaft Of The Radial Fan And Is Deflected By 90° By The Rotation Of The Rotor And Discharged Radially.

The Experimental Unit Provides The Basic Experiments To Get To Know The Operating Behaviour And The Most Important Characteristic Variables Of Radial Fans.

It Features A Radial Fan With Variable Speed Via A Frequency Converter, An Intake Pipe And A Delivery Pipe. The Transparent Intake Pipe Is Fitted With Guide Plates For Flow Guidance And With A Flow Straightener To Calm The Air. This Enables Precise Measurements Even With Heavily Reduced Operation. The Air Flow Is Adjusted By A Throttle Valve At The End Of The Delivery Pipe.

Learning Objectives And Experiments

- Operating Behaviour And Characteristic Variables Of A Radial Fan

- Recording The Fan Characteristic (Pressure Difference As A Function Of The Flow Rate)

- Effect Of The Rotor Speed On The Pressure

- Effect Of The Rotor Speed On The Flow Rate

- Effect Of Different Blade Shapes On The Fan Characteristic And Efficiency

- Determination Of Hydraulical Power Output And Efficiencies

Features

- 2 Interchangeable Rotors

- Transparent Delivery Pipe And Intake Pipe

- Software For Data Acquisition, Visualisation And Operation

- Part Of The Labline Fluid Energy Machines

Specification

- Functioning And Operating Behaviour Of A Radial Fan

- Radial Fan With 3-Phase AC Motor

- Variable Speed Via Frequency Converter

- Transparent Intake And Delivery Pipes

- Throttle Valve To Adjust The Air Flow In The Delivery Pipe

- Interchangeable Rotors: 1 Rotor With Forward Curved Blades And 1 Rotor With Backward Curved Blades

- Determination Of Flow Rate Via Intake Nozzle

- Display Of Differential Pressure, Flow Rate, Speed, Electrical Power Consumption And Hydraulical Power Output, Temperature And Efficiency

- Due To Integrated Microprocessor-Based Instrumentation No Additional Devices With Error-Prone Wiring Are Required

- Display And Evaluation Of The Measured Values As Well As Operation Of The Unit Via Software

Technical Specification

- Intake Pipe

- Inner Diameter: 90mm

- Length: 430mm

- Delivery Pipe

- Inner Diameter: 100mm

- Length: 530mm

- Radial Fan

- Power Consumption: 110W

- Nominal Speed: 2800min-1

- Max. Volumetric Flow Rate: 480m3/H

- Max. Pressure Difference: 300Pa

- Measuring Ranges

- Differential Pressure: 0…1800Pa

- Flow Rate: 0…1000m3/H

- Temperature: 0…100°C

- Speed: 0…3300min-1

- El. Power Consumption: 0…250W

- 230V, 50Hz, 1 Phase

- 230V, 60Hz, 1 Phase; 120V, 60Hz, 1 Phase