Study Of A Pre Tensioned Bolt

Analysis can be made of the stresses and strains produced in a bolt after different methods of tightening, and allows modelling of the behaviour of a bolted connection when axially loaded.

Teaching objectives

The apparatus allows the following experiments:

- Deformations in a bolt after tightening with a spanner or with a torque wrench.

- Effect of bolt pre-tensioning using a hydraulic loading system.

- Effect of varying the loading position.

- Effect of varying the materials on the loading torque.

- Static analysis of sliding with friction on a helical screw contact surface or plane.

- Simple loading and stresses on a plane section.

- Mohr’s Circles of stress, principal stresses and their directions.

Technical specifications

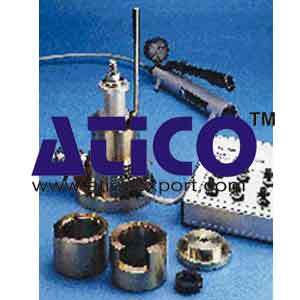

The pre-loaded bolt assembly is composed of :

- A 16mm bolt on which are fixed three pairs of diametrically opposed 45° strain. These permit the measurement of extension and tension in the bolt.

- A tubular component with 2 strain gauges mounted at 180° to measure the compression in the assembly at different heights.

- A loading tube to apply bolt pre-load or to apply loading force at various positions along the bolted assembly.

- A manually operated hydraulic pump.

- A micrometer dial gauge to measure extensions over the complete assembly.

- Nuts and washers of various materials.

Equipment Package :

- Pre-loaded bolt assembly with hydraulic loading system and manual pump.

- A set of washers.

- Technical manual and teaching notes.

Dimensions and weight

- 15 diam. x 37 cm – 12 kg

- Pump: 40 x 10 x 14 mm – 3,5kg

Essential requirements

- Electrical supply : 220V, 50 Hz

Additional required equipment :

- Extensometer bridge.

- A ring spanner 24 mm.

- A torque wrench of capacity 40 – 200 Nm with 24 mm nut.